HiPIMS Magnetron Sputtering: A New Trend in Material Preparation

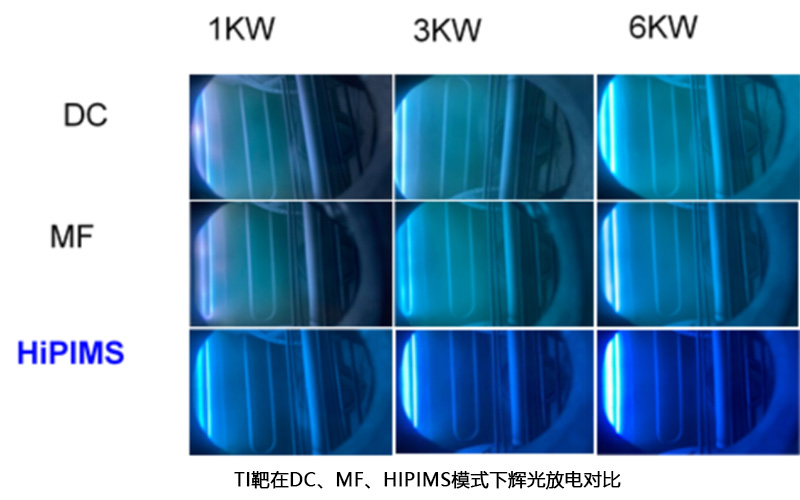

In the field of material preparation,HiPIMS(High Power Pulse Magnetron Sputtering)magnetron sputtering is gradually emerging as a new development trend.

HiPIMS magnetron sputtering technology has unique advantages.Compared with traditional magnetron sputtering,it can operate in high-power pulse mode and generate high-density plasma.This enables the sputtered atoms or ions to have higher energy and activity,allowing for better control of the microstructure of the thin film during material deposition.For example,it can form a more dense,uniform,and well crystallized thin film coating,significantly improving the performance of materials such as hardness,wear resistance,corrosion resistance,etc.In the preparation of tool coatings,the coating obtained by HiPIMS magnetron sputtering can greatly extend the service life of the tool and improve cutting efficiency.

From the perspective of material diversity,HiPIMS magnetron sputtering is almost suitable for the preparation of various metals,alloys,ceramics,and other materials.Whether it is common stainless steel,aluminum alloy coatings,or new functional ceramic films,high-quality deposition can be achieved through this technology.This provides a vast space for the development of new materials with special properties,which can meet the growing demand for high-performance materials in many industries such as aerospace,electronics,and automotive.For example,in the electronics industry,high dielectric constant thin film materials prepared by HiPIMS magnetron sputtering can help improve the performance and miniaturization of electronic components.

In terms of environmental protection,HiPIMS magnetron sputtering also performs well.Due to its high ionization rate and deposition efficiency,compared to some traditional material preparation processes,it can reduce the waste of raw materials and the emission of harmful gases.In today's world where sustainable development has become a global consensus,this feature makes HiPIMS magnetron sputtering more in line with the concept of green manufacturing,which is conducive to promoting the transformation and upgrading of the material preparation industry towards environmental protection.

However,HiPIMS magnetron sputtering technology is not perfect either.The equipment cost is relatively high,and the technical operation is complex,requiring professional technicians to maintain and regulate it.But with the continuous development and popularization of technology,these problems are expected to be gradually solved.In summary,HiPIMS magnetron sputtering,with its advantages in material performance improvement,material diversity,and environmental protection,is undoubtedly a new trend in the field of material preparation and will play an increasingly important role in future materials science and engineering.

0769-81001639

0769-81001639