High Power Pulsed Magnetron sputtering Technology (Part I)

High-power pulsed magnetron sputtering (HiPIMS), proposed by Kouznetsov1 et al. 1999, is a promising magnetron sputtering technology developed on the basis of pulsed power technology. In order to distinguish this technique from other pulsed magnetron sputtering techniques, it is generally defined as 2: HiPIMS is a magnetron sputtering technique in which the peak power usually exceeds the average power by two orders of magnitude. Interest in this technology has increased over the past 20 years.

The main feature of HiPIMS is the combination of standard magnetron sputtering with pulsed plasma discharges, with the aim of producing highly ionized plasma 3 through a large amount of ionized sputtering material. The film deposited by high ionization of sputtering material has the characteristics of smooth and dense film layer 4. For reaction-deposited compound films 5,6, HiPIMS can regulate their phase composition,7 microstructure, 8 and mechanical, 9 and optical properties. Related studies have shown that it has outstanding performance in improving adhesion of thin films, 10 capable of depositing uniform films on substrates with complex shapes, 11,12 and with low deposition temperatures. HiPIMS has the potential of industrial development because of its advantages.

I. Reasons for high ionization rate plasma produced by HiPIMS:

In glow discharge processes such as magnetron sputtering, it is often difficult to achieve a large amount of ionized sputtering materials. When the deposited plasma contains more ions than atoms, this is called an ion coating (IPVD). Several different IPVD technologies are currently available, such as post-evaporation ionization: an RF coil placed in a deposition chamber generates ions that, when negatively biased, accelerate their arrival to the substrate surface. Another technique is cathodic arc evaporation, which takes advantage of the fact that local extremely high current discharges can produce highly dense plasmas, producing highly ionized plasmas around specific points 18,19.

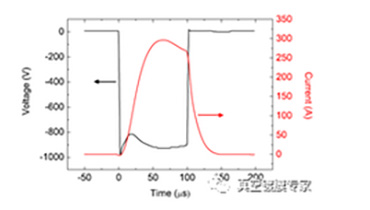

Another way to implement IPVD is to use HiPIMS. HiPIMS can be set up in a traditional magnetron sputtering system to provide a peak power of several kilowatts per square centimeter of high-power pulses by changing the power supply, and can avoid damage to the magnetron target 20, as shown in FIG. 1. The pulse length is usually maintained in the range of 10 to 500μs21,22 and the pulse frequency ranges from tens of Hertz to kilohertz. In most HiPIMS processes, the voltage applied during the pulse is usually around 500 to 1000 V, and the peak current density (peak discharge current/target area) reaches a maximum of a few amperes per square centimeter 24. By using a very high instantaneous power density for the magnetron cathode, the charge carriers in front of the target increase substantially during HiPIMS pulses. Numerically, this means that for HiPIMS discharge, the electron density in the ionization region close to the target surface is on the order of 1018 to 1019 m-3 25,26. For sputtering metal atoms with electron density of about 1019m-3, the mean ionization free path is about 1 cm, while for DC magnetron sputtering (DCMS) discharge with electron density of 1017 m-3, the mean ionization free path is about 50 cm27. Thus, due to the high electron density in HiPIMS discharges, a large portion of the sputtered material is thus ionized.

Figure 1. Voltage and current characteristics of typical high-power pulsed Magnetron sputtering (HiPIMS) discharge pulses. This figure shows that Cu is powered down at 1.33Pa, and the peak current density reaches about 1.6 A cm-2.

18922924269

18922924269