Characteristics of vacuum coating

Compared with wet coating technology, vacuum coating technology has the following advantages:

(1) The selection of film material and substrate material is wide, the film thickness can be controlled, and a variety of functional films with different functions can be prepared.

What are the methods of vacuum coating?

(1) Vacuum evaporation: clean the substrate that needs to be coated and put it into the coating chamber. After vacuum, the membrane material is heated to a high temperature, so that the water vapor reaches about 13.3Pa, and the water vapor molecules fly to the surface of the substrate and condense into a film.

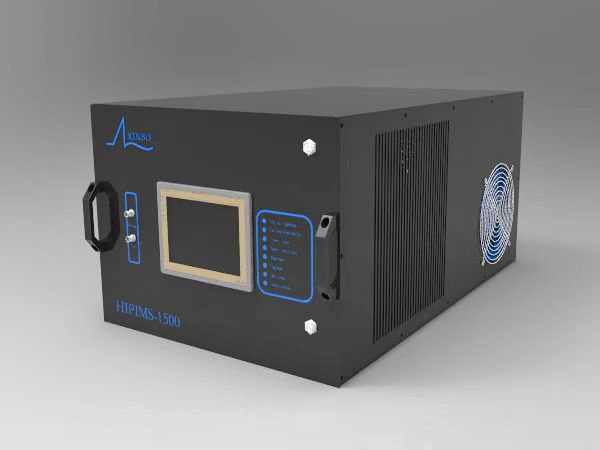

Working principle of HIPIMS pulsed magnetron sputtering

Pulsed magnetron sputtering is a kind of magnetron sputtering which replaces the traditional DC power supply with a rectangular wave voltage pulse supply

Magnetron sputtering technology is divided into direct current (DC) magnetron sputtering, medium frequency (MF) magnetron sputtering and radio frequen

Vacuum magnetron sputtering coating, vacuum evaporation coating magnetron sputtering can be divided into DC magnetron sputtering, medium frequency (MF) magnetron sputtering,

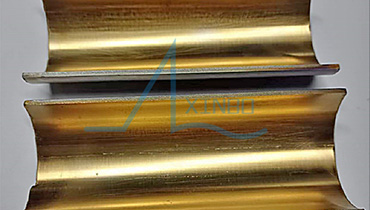

Difference between vacuum magnetron sputtering coating technology and vacuum evaporation coating technology

Vacuum magnetron sputtering coating technology is different from vacuum evaporation coating technology. Sputtering refers to the phenomenon of nuclear particles bombarding a solid surface (target), so that solid atoms or molecules are ejected from the surface.

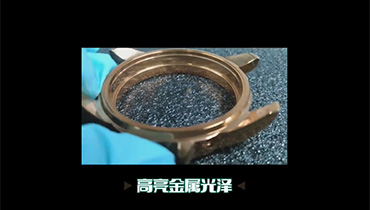

Decorative coating for watch

New Platinum Technology (Dongguan) Co., Ltd. focuses on high energy plasma surface engineering hardware and technology.

Coating of kitchen knife edge display

Video takes you to learn about new Platinum technology tool coating

0769-81001639

0769-81001639