Xinbo focus on

What is Glow?...

Xinbo Technology (Dongguan) Co., Ltd. was established in 2020. It is a national high-tech enterprise specializing in R&D, manufacturing, and marketing of vacuum coating systems. It has 4 assembly production lines and 5 testing and debugging lines, which covers a total area of 2,000 square meters.We focus on providing high power plasma surface engineering solutions and devices to customers in the growing coating industry

Proportion of R&D personnel

Publish academic papers

Customer praise

Collaborative research and development of the project

Custom development projects

New Platinum Technology (Dongguan) Co., Ltd. focuses on high energy plasma surface engineering hardware and technology....

Video takes you to learn about new Platinum technology tool coating...

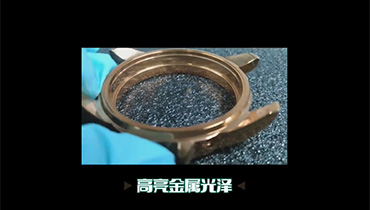

With the development of the economy and the improvement of living standards, people like the hand watch case, watchband, clothing, lighting, glasses frame, indoor and outdoor...

PVD metal vacuum coating has the advantages of strong binding force, long color protection time and strong wear resistance, which is superior to traditional electroless plating to a certain extent. So can this vacuum coating process replace the traditional chemical coating process? The answer is no, at least for now....

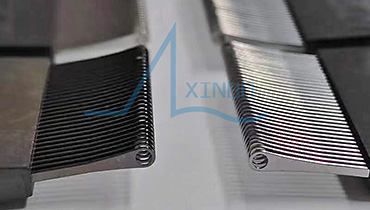

Vacuum magnetron sputtering coating technology is different from vacuum evaporation coating technology. Sputtering refers to the phenomenon of nuclear particles bombarding a solid surface (target), so that solid atoms or molecules are ejected from the surface....

In chemical vapor deposition (CVD) vacuum coating, the selection and ratio of reaction gases are like a pair of invisible but powerful hands, playing a decisive role in the composition and properties of the coating....

HIPiMS technology can effectively regulate the microstructure of thin films during the deposition process by controlling a series of process parameters. These parameters include but are not limited to power, pulse frequency, gas pressure, substrate temperature, etc. The following is a detailed explanation:...

HiPIMS (High Power Impulse Magnetron Sputtering) is a thin film deposition technique that utilizes high-density plasma generated by a high-frequency pulse power source for material sputtering deposition....

Vacuum coating and electroplating, as two common surface treatment technologies, differ significantly in a number of ways. The following is a detailed description of the differences between the two:...

Due to the constraint of magnetic field and the ultra-high power discharge, the high-power pulsed magnetron sputtering technology (HiPIMS) has the unstable phenomenon of glow flicker due to the partial discharge enhancement during the discharge process....

The influence of HIPiMS technology(high-power pulsed magnetron sputtering technology)on material properties is mainly reflected in the microstructure,density,mechanical properties,...

In the coating process,the characteristics of the coating material have a crucial impact on the coating effect....

In the coating process,different coating equipment has their own unique characteristics and advantages....

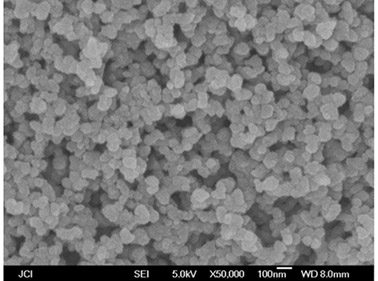

We all know that nanoparticles have self aggregation effect due to their large surface energy. On a flat surface, a layer of nanoparticles is stacked on the surface. With the rise of temperature, ...

LINKS :