What are the advantages of PECVD protection technology

PECVD (Plasma Enhanced Chemical Vapor Deposition) is a technique for depositing thin films, widely used in semiconductor manufacturing, solar panel production, display manufacturing, and other fields. Compared with traditional CVD (Chemical Vapor Deposition) technology, PECVD has multiple advantages, especially in terms of protection, as follows:

Low temperature deposition: PECVD can operate at lower temperatures, which means it can be used for sensitive materials or substrates that cannot withstand high temperature processing. This is particularly important for applications that require depositing thin films on plastic or flexible substrates.

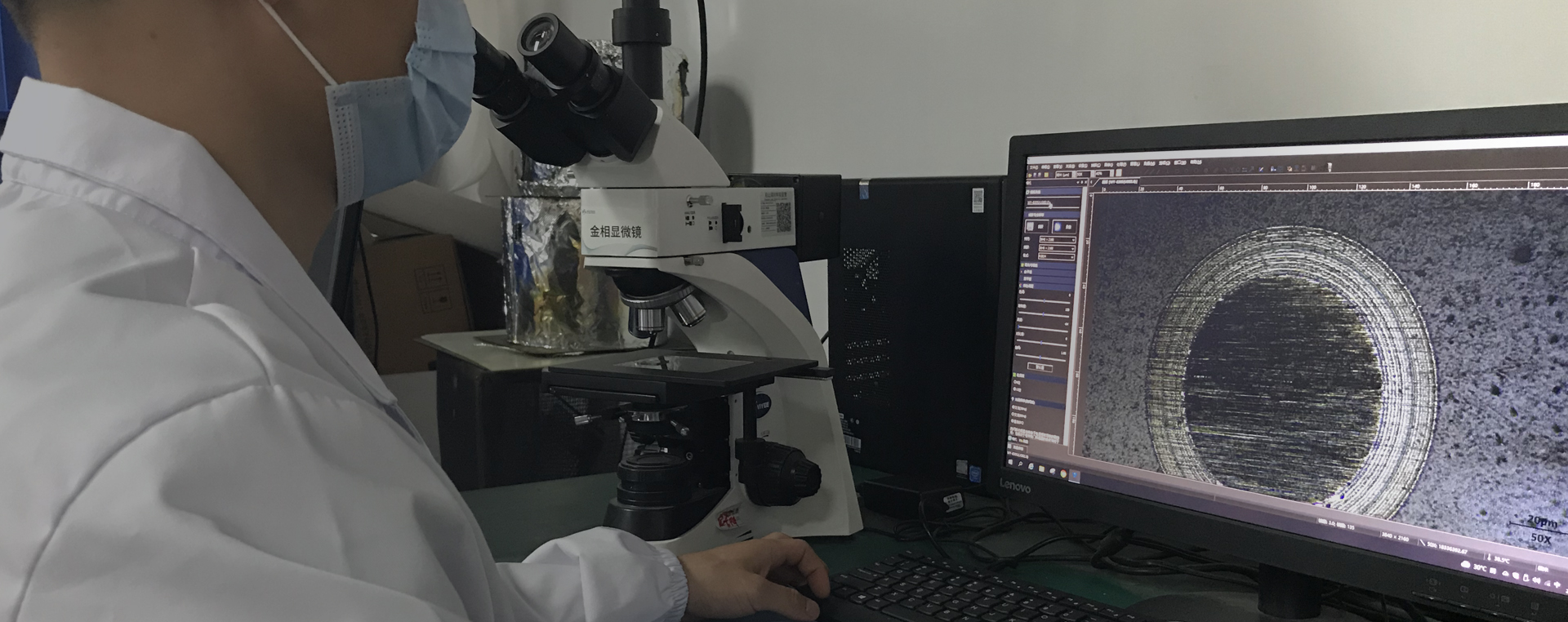

Uniformity: Plasma enhancement technology can promote the decomposition of reactant molecules, resulting in more uniform film deposition. Even on surfaces with complex shapes, consistent coatings can be formed.

Enhanced film quality: Thin films prepared by PECVD typically have good density and purity, as plasma can increase reaction activity and help form high-quality deposition layers.

Improving adhesion: The high-energy particles generated during PECVD can improve the interaction between the film and the substrate, thereby enhancing adhesion and reducing the risk of delamination.

Multifunctionality: PECVD technology can be used to deposit various types of thin film materials, including insulators, conductors, and semiconductors, providing flexibility for different applications.

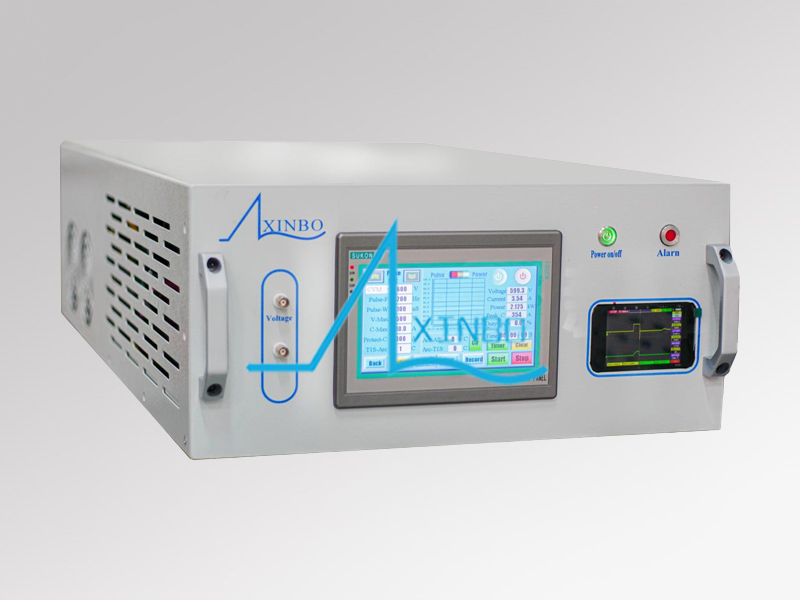

Strong controllability: The thickness, composition, and performance of the film can be finely controlled by adjusting plasma conditions such as power, gas composition, pressure, etc., so that the product can meet specific requirements.

Cost reduction: PECVD can operate at lower temperatures, resulting in lower energy consumption and reduced demand for expensive high-temperature equipment, which helps to lower overall production costs.

Environmentally friendly: PECVD technology may use fewer toxic chemicals compared to some traditional deposition methods, reducing the risk of environmental pollution.

Improving production efficiency: Due to PECVD's ability to achieve rapid deposition, it helps to increase the throughput of the production line and shorten the production cycle.

Good compatibility: PECVD equipment is usually designed to be modular and easy to integrate into existing manufacturing processes, without the need for large-scale modifications to existing facilities to introduce new technologies.

In summary, PECVD technology not only provides excellent thin film protection characteristics, but also has various operational conveniences and economic benefits, making it an indispensable part of modern manufacturing.

0769-81001639

0769-81001639